Product Description:

PVC Insulated Thermocouple & Extension Wire (Max. Temperature: 105°C)

Model explanation:

Nominal Insulation Thickness:

|

Wire Size (AWG) |

Conductor Insulation Thickness (mm) |

Jacket Insulation Thickness(mm) |

Outer Diameter(mm) |

|

14 |

0.38 |

0.45 |

3.2x5.6 |

|

16 |

0.38 |

0.38 |

2.8x4.9 |

|

16 7/14 |

0.38 |

0.38 |

3.0x5.0 |

|

20 |

0.38 |

0.38 |

2.3x3.9 |

|

20 7/28 |

0.38 |

0.38 |

2.4x4.1 |

|

24 |

0.38 |

0.38 |

2.0x3.3 |

|

24 7/32 |

0.38 |

0.38 |

2.1x3.5 |

PVC-PVC Physical Properties:

|

Characteristics |

Insulation |

Jacket |

|

Abrasion Resistance |

Good |

Good |

|

Cut Through Resistance |

Good |

Good |

|

Moisture Resistance |

Excellent |

Excellent |

|

Solder Iron Resistance |

Poor |

Poor |

|

Service Temperature |

105℃ continuous 150℃ single |

105℃ continuous 150℃ single |

|

Flame Test |

Self-extinguishing |

Self-extinguishing |

Applications:

Thermocouple Cable is the wire which has the similar thermoelectric properties with thermocouple in a certain temperature range.

The thermocouple total potential value only relate to the temperature of hot end and reference junction without influence of intermediate temperature. So compensation could extend the heat to the meter terminal instead of expensive compensation wire.

Thermocouple cable not only measurement errors but also can improve physical and mechanical properties of thermocouple line

Multi-strand core or small diameter wire compensation can improve the flexibility of the line and make the connection convenient. Besides, It is easy to shield from outside interference and reduce the Road costs for measurement line.

Competitive Advantage:

1.Our

measurement accuracy of thermocouple cable can reach the level of grade 1

2.10,000 meters without joints

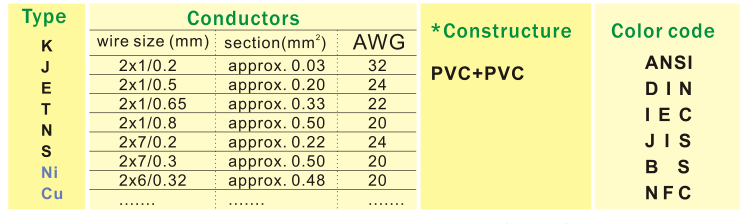

3.The color-coded can meet the requirements of (ASNI, DIN, JAP, IEC ... etc)