Product Description:

FEP Insulated Thermocouple & Extension Wire (Max. temperature: 200°C)

Thermocouples are widely used to measure temperature. This works on the thermoelectric effect; whereby a metal will generate a voltage when heated. By taking the differential voltage generated when two different metals in the same circuit are heated it is possible to measure changes in temperature as a change in voltage.

In order to get an accurate measurement, expensive metals are commonly used within the temperature probe itself. For long cable runs however, the cost of these metals becomes prohibitive and for that reason Cable manufacture a range of extension and compensation cables. As standard, Cable offers Class 1 thermocouples which provide the tightest tolerance and most accurate measurements.

Compensating cable is of different composition to extension cable (it uses alternative, cheaper alloys) but has a similar temperature. relationship over a limited range, and should only be used for joining thermocouples to their measuring instruments. It can only be used in limited ambient temperature, generally not higher than 800℃。

Also, compensating cable is less accurate than extension cable in terms of thermal tolerance values (typically double).

With long cable runs, the cable may need to be screened and earthed at one end (at the instrument) to minimize noise pick-up (interference) on the measuring circuit. Alternative types of screened cable construction are available and these include the use of copper or Mylar screening.

Technique parameter:

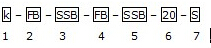

Model explanation

Nominal Insulation Thickness:

|

Wire Size (AWG) |

Conductor Insulation Thickness (mm) |

Jacket Insulation Thickness (mm) |

Outer Diameter (mm) |

|

14 |

0.20 |

0.25 |

2.6×4.8 |

|

16 |

0.20 |

0.25 |

2.2×3.9 |

|

16 7/24 |

0.20 |

0.25 |

2.4×4.3 |

|

20 |

0.20 |

0.25 |

1.7×2.9 |

|

20 7/28 |

0.20 |

0.25 |

1.8×3.1 |

|

24 |

0.20 |

0.25 |

1.4×2.3 |

|

24 7/32 |

0.20 |

0.25 |

1.6×1.7 |

FEP-FEP Physical Properties:

|

Characteristics |

Insulation |

Jacket |

|

Abrasion Resistance |

Very good |

Very good |

|

Cut Through Resistance |

Good |

Good |

|

Moisture Resistance |

Excellent |

Excellent |

|

Solder Iron Resistance |

Good |

Good |

|

Service Temperature |

200℃continuous 250℃single |

200℃continuous 250℃single |

|

Flame Test |

Self-extinguishing |

Self-extinguishing |

Applications:

Thermocouple extension cable consists of conductors of the same nature as the elements of the thermocouple and which extends this to the thermocouples’ reference junction.

Commonly there are four types of insulation material for extension cable: fiberglass, Teflon, PVC and silicone. Stainless steel braided and tinned brass braided is also commonly used in the cable.

Customers from different areas possibly require different color style for the cable, all color standard are available upon request.

Competitive Advantage:

1.Our

measurement accuracy of thermocouple cable can reach the level of grade 1

2.10,000 meters without joints

3.The color-coded can meet the requirements of (ASNI, DIN, JAP, IEC ... etc)